by Paul Carter |

February 03, 2016

Woodturners at Carter and Son Toolworks share seven tips they've found to be invaluable. Enjoy, and happy turning!

1. The tailstock is your cheapest insurance. Whenever possible, take advantage of the tailstock. It comes with your lathe and a stable, secure piece is always easier to work with.

2. Ride the bevel. Pay attention to how you're using your tools. Take it slow and remember to ride the bevel.

3. Use sandpaper like someone else is paying for it. Don't overuse the same piece of sandpaper, an 800 grit piece can quickly become dull.

4. A sharp tool is a safe tool. Sharpening can be a difficult skill to master, but it is essential to woodturning. Sharp tools are safer and more enjoyable to use. Be patient and take the time to learn to sharpen, it will pay off.

5. You see better with your hands. Don't just look at your work, feel it. Oftentimes your hands can best assess the shape and smoothness of a piece.

6. Master the basics. Every aspect of woodturning is based on some basic skills that are critical to learn. Don't feel rushed to learn complicated cuts, master the basics.

7. Practice. Spend time at the lathe, it makes all the difference!

Questions or tips of your own? Share in the comments below.

Tagged:

turning tips,

turning tools,

wood for turning,

wood turning,

woodturners,

woodturning,

woodturning blog,

woodturning tools,

woodworking,

woodworking blog

by Paul Carter |

April 20, 2015

Watch Your Sandpaper: Sandpaper is a cutting tool, keep it sharp and keep it clean. Don’t try to reuse and recycle your sandpaper, your piece will suffer.

Oil & Sandpaper: For a finer look, apply oil to the wood using 600 grit wet/dry paper or shavings. The friction caused by the heat will cure the oil faster. You can also apply this technique to wax finishes.

Rotary Sanding Disk: If you have lots of finishing to do, try using a rotary sanding disk. This method is faster than sanding by hand and oftentimes leaves a smoother finish with less scratches.

Use the Tools: Don’t be afraid to go back to your tools if a coarse grit of sandpaper isn’t doing the job.

Try Tung Oil: Many turners dismiss tung oil because of the time it takes to dry. Tung oil leaves a beautiful, watertight finish that may be worth the wait.

Don’t Skimp: Take your time finishing your piece. The better it looks now, the better it will look on display later. Finishing is important, don’t treat it as an afterthought.

What are your favorite finishing techniques? Let us know in the comments below!

Sources:

http://www.woodcentral.com/russ/finish7.shtml

http://www.morewoodturningmagazine.com/articles/finishing.php

Tagged:

finishing,

finishing wood,

how to finish wood,

sanding tips,

sandpaper,

tip and techniques,

turning,

turning tips,

turning tools,

wood for turning,

wood turning,

woodturners,

woodturning,

woodturning blog,

woodturning tools,

woodworking,

woodworking blog

by Valerie and Paul Carter |

November 19, 2014

Many turners have walked into their favorite woodworking store, checked the price tag on a beautiful bowl blank, and nearly fainted. Why is wood so expensive and how can you find, and turn, free wood?

For spindle work most turners look for seasoned wood. You can find inexpensive chunks of seasoned wood for your spindle work from several sources:

- Narrow pieces of wood that wood dealers have a hard time selling.

- Discarded wood from cabinet or furniture makers. Oftentimes called 'drop.'

- Firewood

- Skids and pallets are a great source of thick timber. Pallets coming from the orient are oftentimes made of beautiful exotic woods.

Faceplate work is generally quite pricey because thick seasoned wood for bowls and the like is considerably harder to dry. There are some places that you can look for great wood for faceplate work, however.

- Road crews that cut down trees are often willing to give away wood.

- Private tree trimming companies are also a great source for free or inexpensive wood.

Most wood you'll find from these sources, however, will not be seasoned. Rather, it will be green wood. A felled tree is about 60% water. As the tree dries water slowly drains from around the cells of the tree until, at last, the cells themselves begin losing water. As it loses water the wood will begin to shrink. This is when the green wood cracks.

Perhaps you're thinking, what's the point of finding free green wood if it will just crack? Thankfully, there are several ways you can avoid cracking.

First of all, the portion of the log that you cut your blank from is critical. It is necessary that, as Ernie Conover, a well-known turner states, "no chunk [of green wood] contains a complete annular growth ring." As shown in this image:

Once you've cut your green wood, it is important to keep the elastic limit in mind. The elastic limit is basically how much a piece of wood can bend before breaks or cracks. As you can imagine, a thinner piece of wood will be able to bend much further before it breaks. That is why large and thick green bowls are more likely to crack while they are shrinking and losing water. Ernie Conover talks about wall thickness, advising that, "a good rule of thumb for wall thickness is to make it no more than 10% of the largest diameter. For a 8" diameter bowl, make the wall 7/8" or less."

After you have roughed out your bowl, allow it to dry for at least 3 months before giving it it's final shape. A good idea is to wrap your bowl in paper while it is drying. This will slow the loss of moisture and help prevent cracking.

Tagged:

buy wood,

carter and son toolworks,

finding free wood,

finding wood,

free wood,

turned,

turning,

turning tools,

wood for turning,

wood turning,

woodturners,

woodturning,

woodturning blog,

woodturning tools,

woodworking,

woodworking blog

by Paul Carter |

September 09, 2014

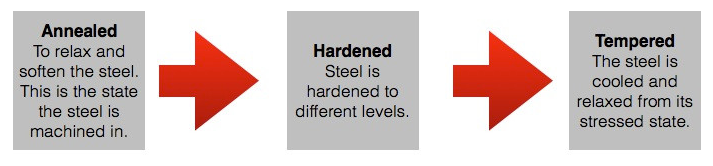

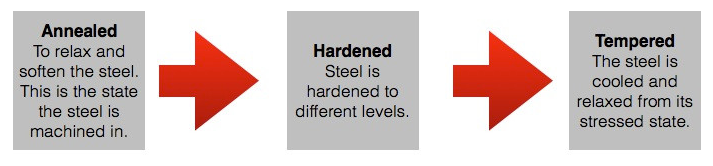

Steel is an amazing material. It comes in an array of types, from stainless to high speed. However, it is often the heat-treatment process that makes steel usable for hundreds of applications.

Steel is shipped from suppliers to machine shops around the world in an annealed state. Because this is the steel's softest and most relaxed state, machining the steel in this form is much easier. Heat-treatment always takes place on annealed steel. Once a steel has been heat-treated, it can be returned to it's annealed state. Steel cannot be re-heat-treated without first being annealed.

Once the steel has been machined, it moves onto heat-treating. The steel is hung on wires and then heated to hundreds of degrees Fahrenheit. Different types or grades of steels can be heat-treated to different harnesses. The steel used for our tools, M42 high speed steel, has a 10% cobalt content. This cobalt allows us to heat-treat our tools harder than most high speed steels, to a hardness of 68 HRC.

After the hardening process, the steel is very brittle and pressured. This is why tempering is the next step in heat-treating. Tempering reduces the internal stress of the steel and increase the steel's robustness.

Once the steel has been tempered it is ready for use in a huge warehouse, machine shop or at your lathe.

Tagged:

carter and son toolworks,

heat treat,

heat-treating,

heat-treating wood turning tools,

turned,

turning,

turning tools,

wood turning,

wood turning blog,

wood turning tools,

woodturners,

woodturning,

woodturning blog,

woodturning tools,

woodworking,

woodworking blog