Why Heat-Treating Is More Than Essential

Steel is an amazing material. It comes in an array of types, from stainless to high speed. However, it is often the heat-treatment process that makes steel usable for hundreds of applications.

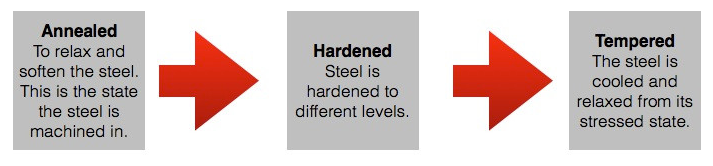

Steel is shipped from suppliers to machine shops around the world in an annealed state. Because this is the steel's softest and most relaxed state, machining the steel in this form is much easier. Heat-treatment always takes place on annealed steel. Once a steel has been heat-treated, it can be returned to it's annealed state. Steel cannot be re-heat-treated without first being annealed.

Once the steel has been machined, it moves onto heat-treating. The steel is hung on wires and then heated to hundreds of degrees Fahrenheit. Different types or grades of steels can be heat-treated to different harnesses. The steel used for our tools, M42 high speed steel, has a 10% cobalt content. This cobalt allows us to heat-treat our tools harder than most high speed steels, to a hardness of 68 HRC.

After the hardening process, the steel is very brittle and pressured. This is why tempering is the next step in heat-treating. Tempering reduces the internal stress of the steel and increase the steel's robustness.

Once the steel has been tempered it is ready for use in a huge warehouse, machine shop or at your lathe.